Intelligent Harvester Head Control (IHC) makes the operator’s work easier and improves delimbing quality

The correct setting of the delimbing knives pressure is a basic requirement for good and precise harvester head operation. Determining the correct settings is based on a number of variables, like tree size, tree species and felling conditions, so finding the correct settings requires experience and expertise.

The Intelligent Harvester Head Control (IHC) option partially automates these settings and makes the operator’s work easier. A sensor in the harvester head measures the force with which the tree is pressed against the harvester head and adjusts the compression pressure of the upper delimbing knives for the best possible delimbing result.

IHC benefits

The force control of the delimbing knives keeps the compression optimal in all conditions. The correct settings ensure good measuring accuracy and delimbing quality as well as low fuel consumption. IHC also improves productivity and the durability of the harvester head.

The compression force of the delimbing knives remains ideal at all times. The tree is compressed against the harvester head with just the right amount of force, resulting in good measuring accuracy.

The operator sets the desired force level for the delimbing knives and the IHC measures the compression force and automatically adjusts it as needed.

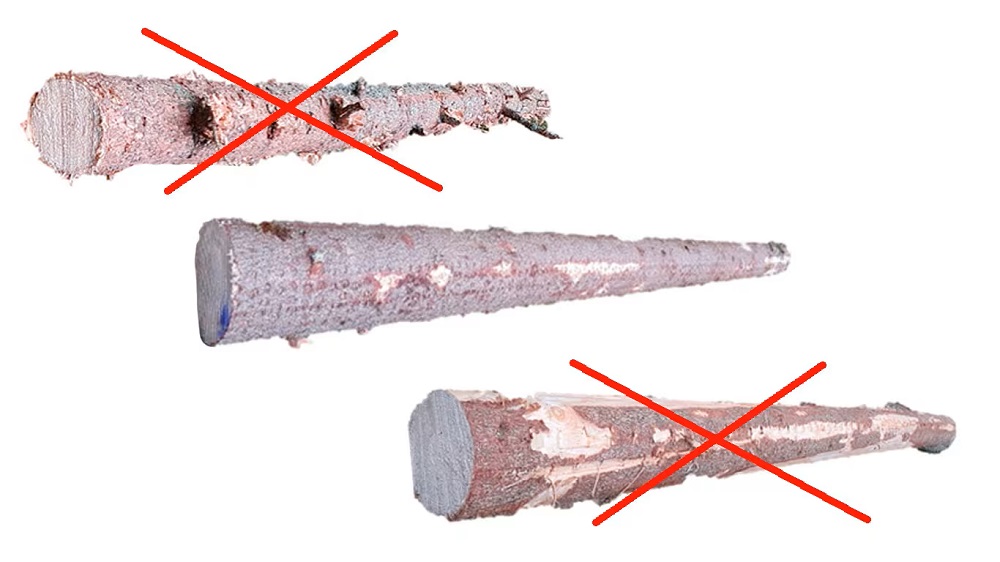

The tree is not debarked and since the knife compression isn’t excessive, the surface layer isn’t damaged and the tree retains its freshness and high value added. Moreover, there is no loosening of the knife grip at the knots as a result of knife pressure that is too low.

The tree is not debarked and since the knife compression isn’t excessive, the surface layer isn’t damaged and the tree retains its freshness and high value added. Moreover, there is no loosening of the knife grip at the knots as a result of knife pressure that is too low.

It may be necessary to change the harvester head settings during the work day. With IHC, there is less need to change the settings because the system automatically corrects them. And even if changes are needed, the adjustments are quick and easy.

With IHC, excessive compression pressure of the delimbing knives is avoided. When the knife is compressed against the tree with just the right amount of force and not too hard, unnecessary fuel consumption is reduced.

With the IHC option, the compression pressure of the delimbing knives doesn’t overstrain the harvester head. This preserves the harvester head structures, as they are not subjected to unnecessary stress.

Tree size, conditions and ways of working impact the amount of force needed to support the tree. A force sensor in the harvester head’s upper delimbing knife measures the contact force between the harvester head and the tree, and the automation adjusts the compression of the delimbing knives so that the tree is compressed against the harvester head with just the right amount of force.

When the customer takes delivery of the machine, it is pre-configured with basic, tree-specific delimbing knife settings, which the operator can also modify.

With the IHC option, the TimberMatic control system has a menu that is used to define the IHC system’s target levels for the contact force between the harvester head and the specific type of tree; based on these target levels, IHC adjusts the compression force. As a starting point, the force levels are set to neutral, which IHC then automatically increases or decreases based on the feeding situation.

The operator no longer has to constantly adjust the harvester head settings as tree characteristics or conditions change because IHC adjusts the compression pressure of the delimbing knives as needed. The operator is left to monitor the harvester head operation and adjust the appropriate force levels of IHC as necessary.

The IHC option is available with H212 and H423 harvester heads.

Pritaikyti pasirenkamus slapukus

| Necessary cookies are cookies necessary for the functioning of the website. | ||

| Analytics cookies are cookies that collect information about how users use the website. | ||

| Advertising cookies are cookies used to deliver advertisements relevant to the user. | ||